In industries such as agriculture, abattoirs, and baling, securing materials quickly, efficiently, and safely is critical to operational success. Hot melt baling strap has emerged as a superior alternative to traditional strapping methods, offering speed, safety, and cost-effectiveness. Whether binding hay bales, securing meat packaging, or compressing recyclable materials, this innovative solution meets the demands of modern industrial operations with ease.

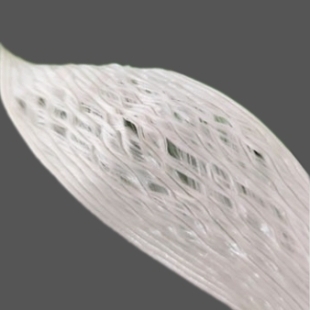

Hot melt baling strap is a type of flexible strapping made from high-tensile polyester fibers bonded together with a specialized adhesive. This manufacturing process results in a strap that combines strength and flexibility, making it ideal for securing heavy or irregularly shaped loads. Unlike steel strapping or twine, hot melt baling strap offers superior performance with minimal effort, improving both productivity and safety.

Agriculture

In the agricultural sector, farmers and suppliers rely heavily on hot melt baling strap for securing hay, straw, and silage bales. Its lightweight yet durable construction allows for easy handling and ensures that bales remain intact during storage and transportation. Additionally, the strap’s resistance to moisture and UV rays makes it an excellent choice for outdoor use.

Abattoirs

For abattoirs and meat processing plants, hygiene and safety are top priorities. Hot melt baling strap provides a safe, non-corrosive, and easy-to-clean alternative to traditional strapping methods. It helps secure meat packaging efficiently while reducing the risk of contamination or product damage during transit.

Baling and Recycling

In recycling facilities, where speed and efficiency are critical, hot melt baling strap excels in compressing and securing bales of cardboard, plastic, and other recyclable materials. Its high tensile strength ensures that bales stay compact, optimizing storage and reducing transportation costs.

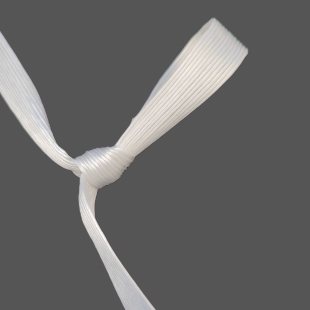

Faster Application

One of the standout features of hot melt baling strap is its ease of use. Compared to steel strapping or twine, it can be applied much faster, reducing downtime and increasing productivity. Workers can easily tie or fasten the strap manually without the need for specialized tools, streamlining the baling process.

Enhanced Safety

Hot melt baling strap eliminates the risks associated with steel strapping, such as sharp edges and potential injuries during handling. Its soft, flexible texture ensures that workers can operate safely and efficiently. Moreover, the strap’s ability to absorb shocks and resist breakage adds an extra layer of safety for both workers and the materials being secured.

Cost-Effective Solution

In addition to its speed and safety, hot melt baling strap is a cost-effective option. It requires less maintenance compared to steel straps, which can rust or need frequent replacement. Its lightweight nature also reduces shipping costs, while its durability ensures fewer replacements, saving both time and money in the long run.

Eco-Friendly Option

As industries shift toward more sustainable practices, hot melt baling strap stands out as an environmentally friendly choice. Many straps are made from recyclable materials, helping businesses reduce their carbon footprint while maintaining operational efficiency.

With advancements in technology, hot melt baling strap has become even more versatile. Modern straps are now available in various widths, strengths, and lengths to accommodate different applications. Some manufacturers have even introduced straps with UV inhibitors and enhanced adhesive properties, ensuring optimal performance in extreme environments.

Additionally, hot melt baling strap can now be integrated with automated baling machines, further increasing efficiency and reducing labor costs. These innovations have made it a go-to solution for businesses looking to streamline their operations while maintaining high safety and quality standards.

As a leader in the production of hot melt baling straps, BSTSTRAP provides high-quality, reliable solutions tailored to various industries. With over 16 years of expertise, BSTSTRAP has developed a range of straps that are strong, durable, and easy to use. The company’s commitment to innovation and sustainability ensures that its products meet the highest standards while addressing the unique needs of its clients.

Whether you’re in agriculture, an abattoir, or a recycling facility, BSTSTRAP’s hot melt baling strap offers the perfect combination of strength, safety, and cost-effectiveness.

Hot melt baling strap is revolutionizing the way materials are secured in agriculture, abattoirs, and baling industries. Its faster application, enhanced safety, and cost-efficiency make it an invaluable tool for businesses seeking to optimize their operations. As the demand for sustainable and reliable solutions grows, hot melt baling strap will continue to play a crucial role in shaping the future of load securing and material management.